FABRICATION OPTIONS

Fabrication Options – Catalog Page Section 3

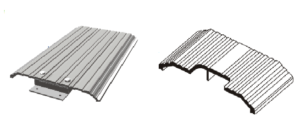

Combination sill and other threshold products can be customized for a variety of applications.

ROUT FOR METAL/MORTISED FRAMES

(RMF) A milling operation to re-move aluminum, enabling the threshold to be “dropped” into place.

Milled to order using exact length, stop size and holes.

TABS

Tabs can be attached to ½” commercial saddle thresholds to facilitate the connection

between thresholds and wood frame.

SILL NOTCH (SN)

is a milling operation to fit the sill

around the frame or trim molding.

Order: Dimensions of notch

required (ie: ”A”, “B” and “C”).

Holes: Three (3) center holes per door.

ROUT FOR METAL FRAMES (RMF)

is a milling operation to remove

aluminum, enabling the threshold to be

“dropped” into place.

MULLION ROUT (MR)

For shop assembly of door, frame, and

lites prior to installation on the job.

Ensures more positive attachment between

sill and jamb.

NAIL-ON ROUT

For wood door frames, using nails or

staples to attach jambs to the

Combo Sills (nail holes provided).

Installation:

Jamb must be cut to match

slope of sill. (Eg. 6 degrees)

Cut left and right jamb

Order: Door opening plus rout size.

Rout Sizes:

R3 = 3/8”, R4 = 1/2”, R6 = 3/4”,

R7 = 7/8”, R8 = 1”, R9 = 1-1/8”,

R10 = 1-1/4”

Holes:

One (1) center hole per door.

Three (3) nail end holes.

NAIL-ON RABBET

For wood door frames, using

nails or staples to attach door

jambs to the Combo Sills (nail

holes provided)

Installation:

Door stop on rabbet jamb

must be cut to match slope of sill.

(5, 6, or 9 degrees). Cut left and right jamb.

Order: Exact length required.

Holes: One (1) center hole per door.

Two (2) end holes. Specify location.